Main Structure

1. Box made by numerical control equipment, advanced technology, smooth lines, elegant appearance

2. Box material is 1.2mm thickness 304SUS stainless steel

3.The air duct in the oven adopt single-cycle system, with import of axial flow fan, To improve the air flow, heat ability, greatly improved the uniformity of the temperature in the cabinet

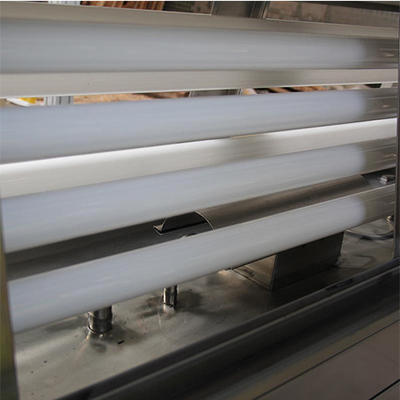

4. Tube: Special uv lamp, 2 rows, 8PCS,40W/PC

5. Lamp Lifetime: more than 1600h

6. Water supply and consumption:Tap water or distilled water about 8L/day

7. Both sides were installed in the studio 8PCS UVA or UVB lamp

8. Heating method: Bladder tank type heating,heat up fast,temperature distribution uniformity

9. Tank cover:double flip,easy shut down.

10. The tank water level automatic filling water, prevent damage of heat pipe air to burn.

11. Sample frame is made from stainless steel or aluminum alloy.

12. Machine bottom using high quality PU wheel fixed

13. Drainage system using U type drainage device

14. The test sample surface with uv light plane in parallel

15. Internal installation of automatic sprinkler spray system, the water pressure is adjustable

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!