Precautions Installation of the balancing machine

1. The compressive strength of the foundation concrete is ≥16MP, the foundation uses No. 525 cement, and the secondary grouting uses No. 625 cement.

2. The installation level of the machine is ≤0.2/1000. The machine needs to be grouted twice after the level adjustment. The grouting should be fully padded, and the anchor bolts should be tightened after the foundation is completely dry.

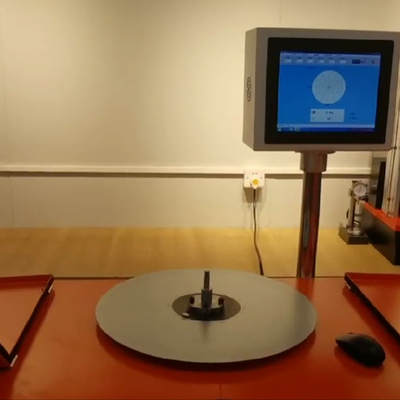

Industrial control measurement system

The measurement system is the core of the balancing machine. This system uses the latest CPU computing chip, after signal amplification, filtering, analog-to-digital conversion, and then computing to display the measurement data. At the same time, it also has the output of database, communication data and control signal, including the connection of printer. Man-machine dialogue interface, intuitive and easy to operate, suitable for display in industrial production environments. After rigorous multi-level component screening, large-scale electrical circuit manufacturing technology, coupled with high and low temperature aging tests, it is suitable for balancing machines to perform accurate measurements in different environments.

Quality Standard

1. accordance with GB/T4201-2006 standards.

2. Quality assurance period: Within 12 months from the completion of commissioning, the product will be maintained for life.

3. Acceptance criteria: Before leaving the factory, the supplier shall check and accept the balancing machine according to the ISO2953-85 standard, and issue a certificate of conformity.

4. Carry out actual operation and on-site acceptance of the physical workpiece at the buyer's place, and complete the training of operators.

After-sales service: 1. After the balancing machine arrives at the buyer's site, the supplier is responsible for the on-site debugging, operation training and common troubleshooting training of the balancing machine. 2. If the equipment fails, our company will respond and support within 48 hours after receiving the buyer's notice. 3. The equipment is free of charge during the "three guarantees", and after the "three guarantees", life-long maintenance services and parts replacement services

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!