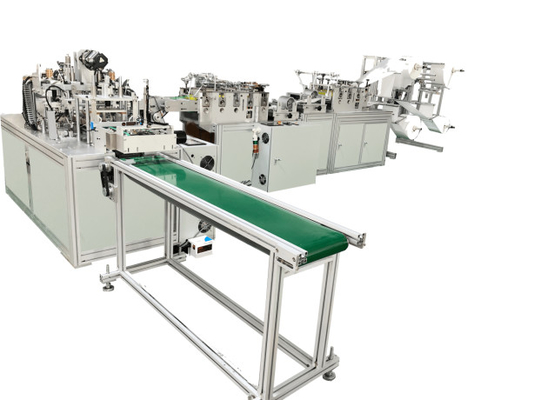

Automatic Medical Face Mask Making Machine Production Line

Product Description

Automatic Medical Face Mask Making Machine Production Line (one with two) use servo and thermostatic control system adopts PL program to control the material from entering compound → forming → welding → punching → spot welding ear belt, and the whole production process is fully automated.Mask machine product features mask machine is made of multi-layer non-woven fabric through hot pressure folding molding, ultrasonic welding, waste removal, ear with nose bridge welding and other processes to produce a variety of masks with constant filtration performance.The production speed of the mask is 80~100 pieces/min, the pass rate is above 97%, and the production efficiency can be more than double compared with similar products.

Feature

PLC-Touch screen - servo - control system;

★ Temperature controller control embossing temperature;

★ Display single shift output and total output on the touch screen;

★ All materials broken material automatic detection and automatic stop;

★ The host's rise and fall speed is set on the touch screen, the current speed of the host (chip/minute) is displayed

synchronously on the touch screen;

★ Automatic stop due to electrical fault.

1. Mask body making system:

The mask body making system is the main part of the mask machine. It is responsible for producing the main part of the mask, welding the three layers of raw materials together, and implanting the bridge of the nose. The body machine can be matched with ear loop welding machine to complete the production of flat masks.

Three size for mask body:

For adult mask, the size is 175 × 95mm;

For child mask, the size is 145 × 95mm;

For baby mask, the size is 125 × 80mm.

2. Ultrasonic earloop welding system:

ltrasonic earloop welding system, automatically cut and weld the earloop to the mask body, using 8 high-speed servo motors, speeds up to 80-90 pieces/min, using square spot welding head, spot welding position is accurate and firm, simple structure, performance stable. And the use of super large exhaust fan, rapid heat dissipation, to ensure the stability of ultrasonic welding. It is commonly used in supporting body machines to form a 1+1 high-speed mask production line. Can also be used stand-alone.

Size Information

1. Power supply voltage: AC380V or 220V 50HZ

2. Power: 8.5 kw

3. Design speed: 80-100 pieces/min

4. Machine size: host: 5700*1900*1750 mm

Packing Details

|

Machine Size

|

5700×1900×1750mm |

|

Mchine Weight

|

Approximately 700KG |

| Delivery Details |

The normal package is wooden box(Size: 3500L*650W*1900H).

If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request.

|

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!